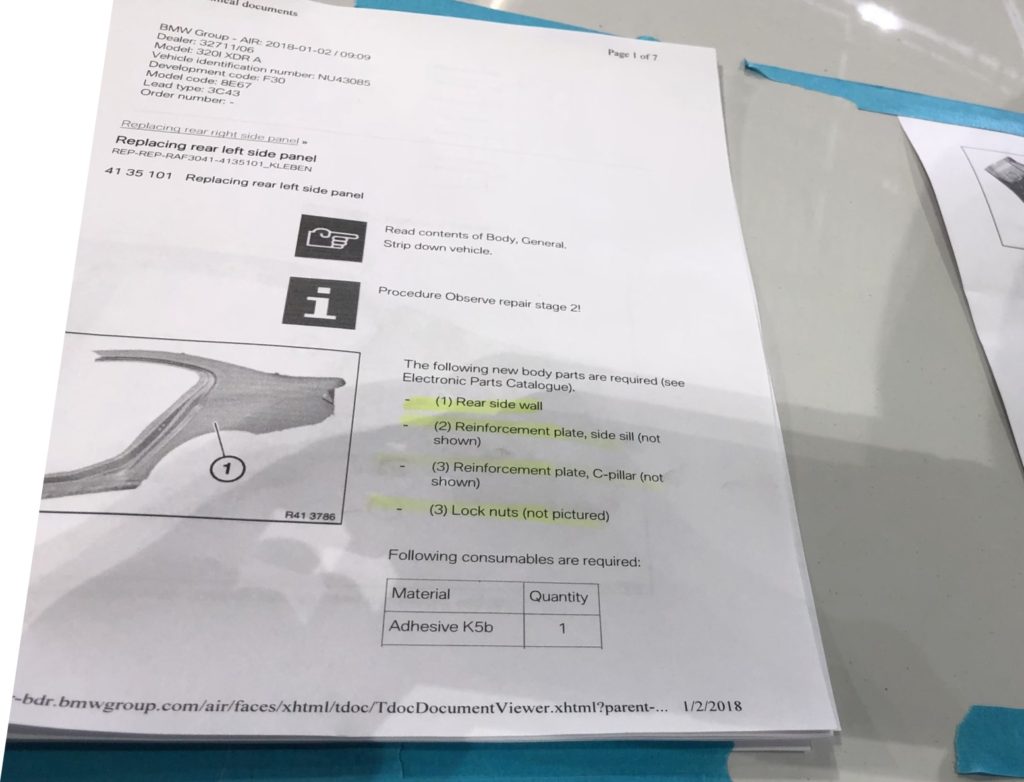

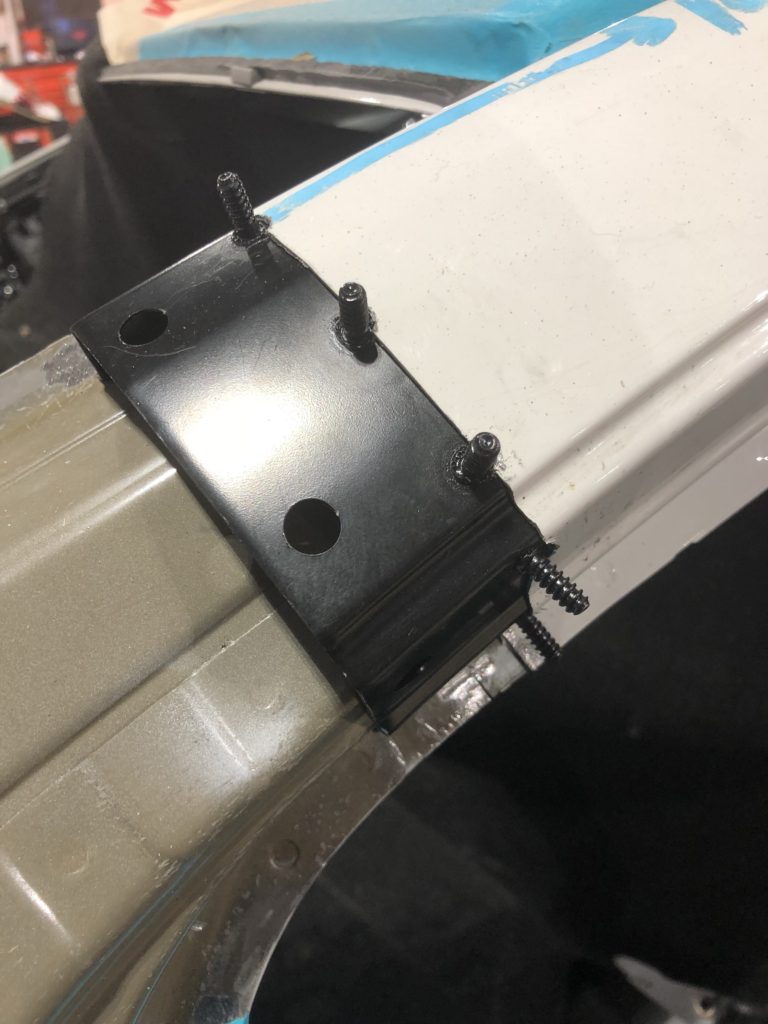

Here are some pictures of the intense process of changing a quarter panel on a BMW 3-Series. It’s essential to follow each step in the repair procedures down to the number of rivets in each section of the panel. Most shops will have not have the tools to do this repair and even less will know (or care) that this is the correct way to repair these vehicles. These pictures are just a sample of the entire process and do not show every step and BMW product that was needed to replace this panel.

This is a section from an I-CAR post discussing BMW’s use of rivet bonding

Click here to go to the full article

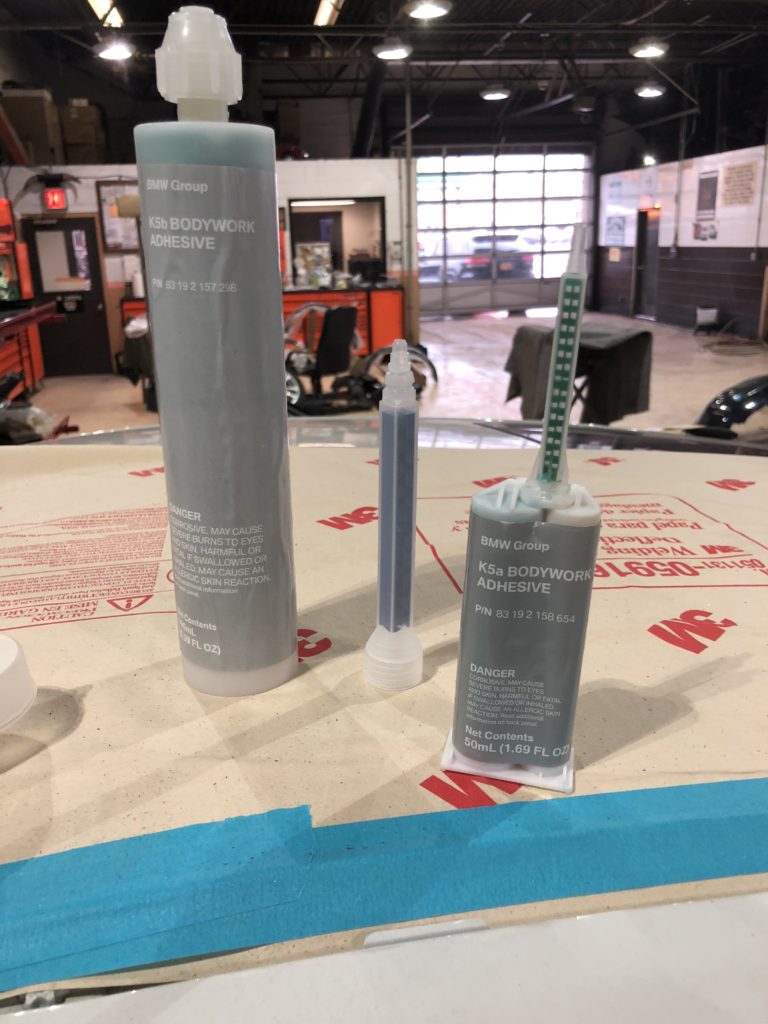

BMW Group has been recommending bonding and rivet bonding techniques to replace damaged aluminum parts for over a decade. The recommendation has now been brought to repairs on steel vehicles. The theory behind the repair of both aluminum and steel parts is similar, although the adhesives and preparation Figure 2 – The repairs on this aluminum front end are similar to the repairs on steel vehicles.material used can vary by the repair situation and the materials being joined (see Figure

Reasons for the Change

There are several reasons that BMW has made the transition from conventional welding and STRSW to bonding and rivet bonding. One of the main reasons is the use of heat-sensitive steel. With bonding and rivet bonding, there is no heat generated that would weaken the steel, allowing the steel to retain its strength.

Another reason for bonding and rivet bonding is the increased corrosion resistance of the repair joints. Corrosion protection is extremely important during repairs because BMW offers a 12-year corrosion warranty.

Tags : BMW 3 Series, Brooklyn Auto Body Repair, Geico Brooklyn Collision Repair, Rivet Bonding